Polyurethane foam

Polyurethane foam has been known in construction for many years. Excellent insulating properties result directly from the structure of foam as a porous material containing an open and closed-cell system. Due to the very low thermal conductivity coefficient, it is ideally suited as thermal insulation for a variety of applications. Foam is also characterized by a very low water absorption coefficient. Thanks to this, it is used, among others, in waterproofing of foundations, terraces, and many other surfaces.

There are two types of polyurethane foam:

1. Open-cell foams

As the name suggests - open-cell polyurethane foam - has in its structure a large number of open cells, thanks to which it "breathes". This allows you to maintain a pleasant environment in the room. Water vapor circulating in the air (resulting from poor ventilation) does not condense on its surface and does not cause mildew.

Where can you use this type of foam? Due to its properties, open-cell foams are used for internal thermal insulation of residential and public buildings. It is advisable to use lightweight open-cell foams applied by spraying to insulate new buildings. They can also be used in existing facilities subjected to thermal renovation.

It is worth remembering that open-cell polyurethane foam is not suitable, due to its properties, for insulating foundations (the ability to absorb water, lack of compressive strength).

2. Closed-cell foams

These type of foams contains a minimum of 90% of closed cells and their density ranges from 30 - 60 kg/m³. It is one of the most effective insulation materials available on the market. Closed-cell foam contains gas bubbles in its structure that makes it possible to obtain the appropriate insulating properties of the material.

This type of foam, due to high density, closed cells, low vapor permeability, and high compressive strength, is ideal for thermal and hydro-insulation of sloped and flat roofs, walls, foundations, livestock buildings, or cold stores.

Spray insulation with polyurethane foam – opinions

Spray insulation with polyurethane foam applied by pressure is considered to be the most effective and fastest-growing thermal insulation technology so far. As the user of one of the construction forums notes:

Polyurethane foams are gaining more and more because they effectively insulate and outperform styrofoam and wool in terms of lambda value = 0.024 W/mK, and the foam spraying on flat roofs is a great solution, quick assembly, no joints, no need to remove the old cover, does not affect for additional roof load, the disadvantage is that it should not be sprayed in the winter and on windy days. Błażej, April 12, 2016, building forum

These optimistic comments result directly from the benefits offered by foam spray insulation. Below you will find the most frequently quoted advantages of this thermal insulator:

- high energy efficiency, due to the exact coverage of all elements requiring insulation,

- it has the best insulation parameters and guarantees tightness,

- homogeneous layer without joints and technological connections,

- durability of the coating,

- adhesion to various substructures,

- it is not slipping or felting,

- it does not absorb moisture,

- it is odorless, resistant to mold, fungi, and bacteria,

- strengthens and dampens the construction structure.

What does the spraying technique look like?

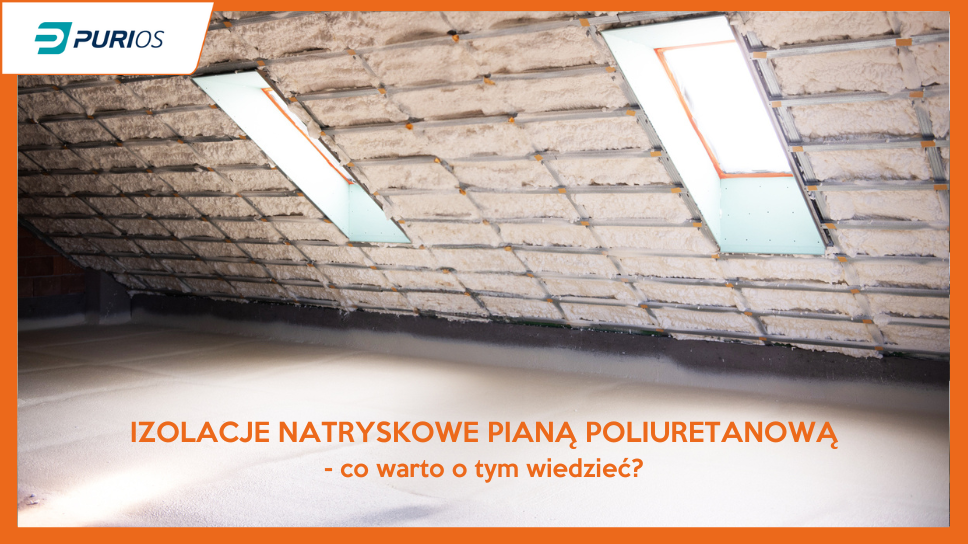

Spray insulation with polyurethane foam is a modern technology of buildings insulation and sealing. High efficiency and ease of application of spray insulation make it a popular way to insulate your house or attic.

How does it look in practice? The two active components of polyurethane foam - polyol and isocyanate - are drawn by pumps to hoses, whereas high-pressure mixing takes place in a spray gun.

Then foam is thrown directly by the gun onto the insulated surface. A few seconds after application, foam increases its volume several times forming a homogeneous, durable insulation layer with excellent thermal and waterproofing properties.

It is worth remembering that foam spray should be made by a professional company. The application of low-pressure aggregates for hydrodynamic spraying should only be carried out by comprehensively trained employees.

This website uses cookies. By using this website, you consent to the use of cookies in accordance with your browser settings.

This website uses cookies. By using this website, you consent to the use of cookies in accordance with your browser settings.