Thermal insulation of the balcony

Most of the balconies in existing buildings are cantilevered structures that are anchored in the tie beam and connected to the ceiling. This type of solution was popular until it turned out how important the thermal insulation of buildings is.

When there appeared a tendency to insulate existing residential buildings, one of the most difficult problems was the elimination of thermal bridges. What is that? The thermal bridge takes place when there is an increased heat flow on the inhomogeneous partition or at the joint of surfaces and materials. Balcony slabs combined with the presence of ceiling tie beam, window lintel, and door sill constitute a real accumulation of thermal bridges.

In currently built houses, to connect balcony slabs with the building structure, prefabricated "balcony connectors" are used. They are specially designed constructions with integrated insulation, which are mounted in the plane of insulation at the stage of tie beam pouring. In addition, linear thermal bridges, which are tie beams and lintels, are insulated with special care. It is worth mentioning that the insulating material of the walls also overlaps with the window opening and specially formed polystyrene "sill blocks" are used for the door sills. That's how it looks in an ideal situation.

Unfortunately, even in new buildings, due to design and implementation errors, an uncontrolled escape of heat from the home may occur. Certainly, you once felt the intense cooling of the zone next to the balcony in a heated room... So how to insulate the balcony?

If you live in a building where there are no balcony insulation connectors, the only option is to insulate the balcony slab on each side, preferably in a jointless manner. Another way is to wrap the slabs on each side, including the forehead, sides, and bottom.

But the easiest and fastest way to do it is by spraying. Spray insulation of closed-cell polyurethane foam turns out to be helpful here. It is surface (also spray) resistant to harmful effects of UV radiation.

To protect against heat loss, just a few centimeters of spraying is enough. It might seem to some of you that this is an unnecessary procedure... But the more effective insulation we apply to the walls of the building, the places where the heat is loss occurs, will be more visible.

"Cold wall" around the sill of the balcony door.

In old buildings, moisture often appears in the balcony door area. The reason may be a thermal bridge or improperly made anti-moisture insulation. If during the thermal renovation of the façade, polyurethane foam is used in the area where the balcony meets the wall and the door sill, besides increased thermal insulation, the waterproofing will be also improved. In this situation, we will benefit from the advantages of polyurethane foam - resistance to changes in moisture and temperature, as well as the ease of forming the product. What is important, the foam can be sprayed onto existing layers of roofing felt, sealing hard-to-reach zones at the joints of the slab and the wall.

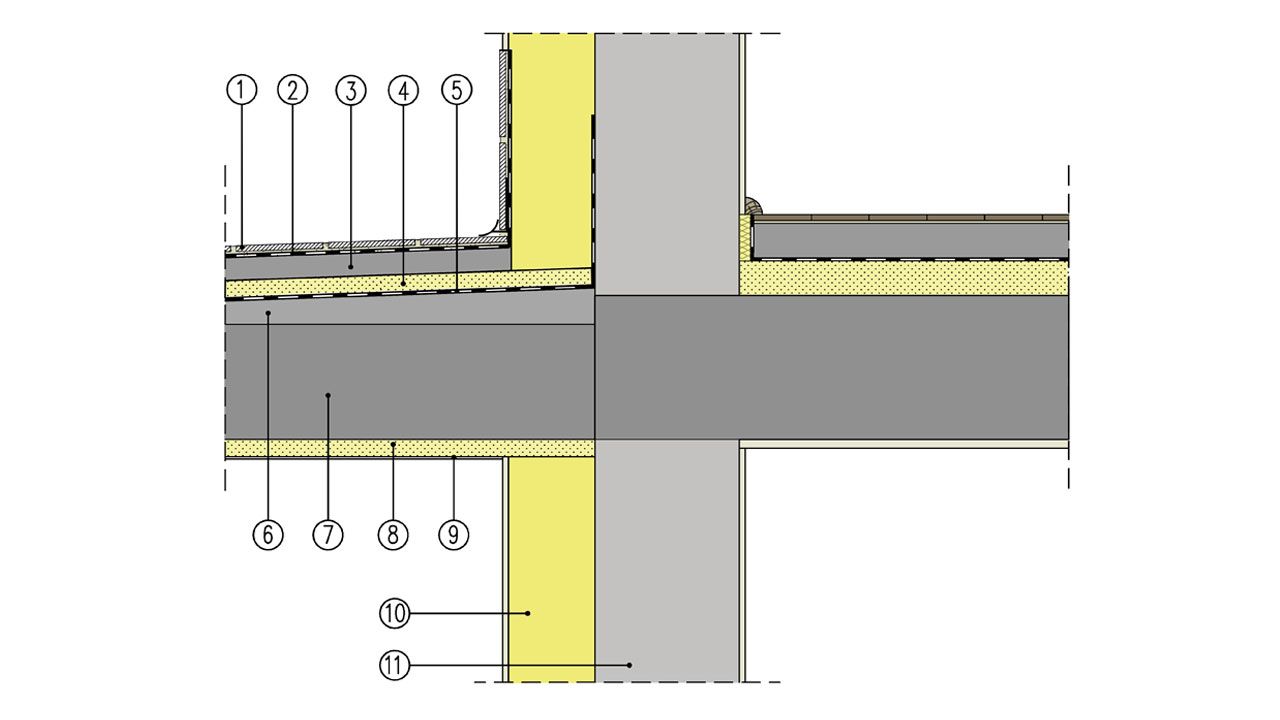

Insulation the balcony slab polyurethane foam

1. Balcony floor - ceramic tiles frost resistant on flexible adhesive mortar

2. The "liquid film" stainless steel insulation coating for external applications

3. Cement screed for external use 3-5 cm

4. Thermal insulation - Purios spray foam

5. Existing internal insulation - roofing paper

6. Existing cement layer - inheritance

7. Existing structural slab, balcony

8. Thermal insulation - Purios spray foam

9. A coating that protects against UV rays

10 Thermal insulation of the external wall

11. External, structural wall

Balcony insulation - how to make it effective?

We like traditional solutions because they are proven. We have got used to the disadvantages of some products, assuming that it can not be otherwise. And what if the technology offers us interesting, modern, and proven solutions?

Spraying of polyurethane foam is at the same time a thermal, acoustic, and anti-moisture insulation. It is formed in a continuous manner. There is also no linear loss of heat or leaks.

Spraying can be applied around the balcony slab and the foam itself is lightweight and does not constitute a large load for the existing structure. There are no additional mechanical connectors in spray insulation and additional coatings are used to ensure full water-tightness. Similarly, to protect against UV radiation - the biggest enemy of polyurethanes - the coatings are used in places of direct exposure.

Using this modern solution, in the next step, we can finish the insulated balcony in a traditional way by sticking frost-resistant ceramic tiles on the floor layer and by spraying mineral plaster on the bottom and sides of the slab.

In a word - to be able to use a beautiful balcony on sunny days, it is worth investing in high-quality polyurethane foam insulation.

Isolation with polyurethane foam

What is the uniqueness of this insulator? In one product, the properties of an insulating material, adhesive mortar, and hydro-insulation were combined. The popularity of polyurethane foam is constantly growing also due to the ease of molding, high flexibility, and tightness.

Foam perfectly fulfills its role in new and existing buildings, and a convenient spraying form makes it possible to reach hard-to-reach places. In most cases, this type of insulation does not require any special preparatory measures or purchase of additional products. Foam, applied in appropriate atmospheric conditions, does not change its properties for many years.

Below you will find another 6 advantages of using polyurethane foam for insulating your balcony:

- The lowest thermal conductivity coefficient among insulation materials, which is not affected by connectors, adhesives, and joints between slabs,

- Spray speed, homogeneity, and continuity of surface coverage,

- Already a small layer of foam is sufficient to perform sufficient insulation,

- The use of closed-cell polyurethane foam does not require vapor barriers and wind insulation,

- Excellent adhesion to any surface,

- Durability of the coating,

This website uses cookies. By using this website, you consent to the use of cookies in accordance with your browser settings.

This website uses cookies. By using this website, you consent to the use of cookies in accordance with your browser settings.