Flat roof insulation — what does it depend on?

The basic decision to make when it comes to thermal insulation of a flat roof is the material. The one you finally choose depends on several factors, such as the arrangement of the layers of particular materials, the way the roof slope is used, and the type of roof. Remember that this process is different for insulating a non-ventilated roof and different for a ventilated roof.

Insulating a non-ventilated roof

Most frequently, the ceiling structure constitutes the roof structure at the same time. In such a case, you must ensure the appropriate roof slope, which can be achieved with a screed layer applied directly on the ceiling slab or through proper arrangement of the external layer of thermal insulation. In some older structures, there is non-ventilated space between the ceiling structure and the roof. At present, such a solution is economically and technically unreasonable.

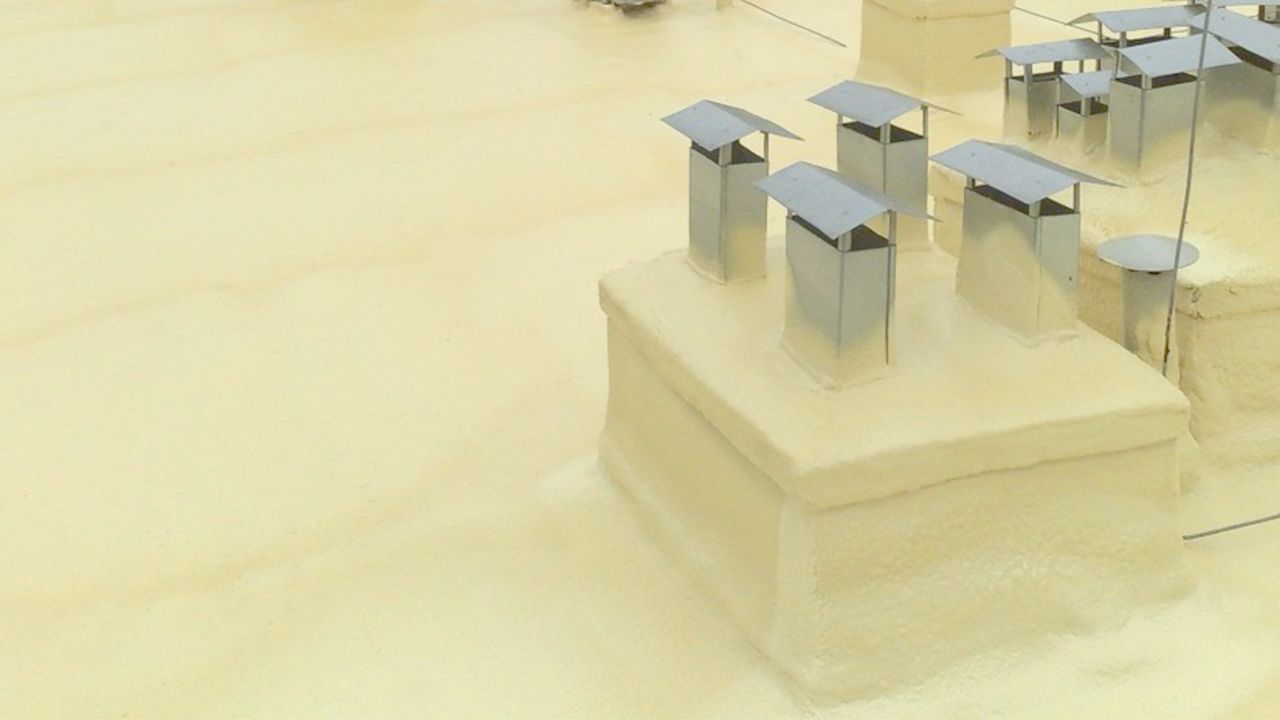

Starting from the bottom: a vapour barrier film is laid directly on the ceiling structure (in some layer systems, a vapour barrier film may be omitted). Then, there are layers of thermal insulation and waterproofing. If you decide to apply thermal insulation first, then what you obtain is the so-called conventional system, while if you choose to install waterproofing first (it can be omitted on the ceiling structure) — the reverse system. External roofing with 3–10% slope may consist of bitumen membrane, heat-welded bitumen membrane (both in at least 2 layers), or PVC/EPDM roof membrane. Other options are a green roof or a ballast roof (with a gravel layer to weigh down the roof).

The so-called non-usable flat roofs, i.e. those that are not subject to useful loads besides periodic servicing, may be thermally insulated with any possible insulating material. The choice of technology and the outermost layer depends on the roof parameters and the expected final result.

Styrofoam boards are most popular, as it is a light and relatively cheap material (besides special types: water absorbing, crumbling, and difficult to process). Its improved version is extruded polystyrene (XPS).

Another possible insulation material are rigid mineral wool boards. Besides its unquestionable advantage of being non-flammable, there are certain weaknesses to this material, which soon become apparent when used on a flat roof. It is a tendency of pressing down over time and significantly reduced insulating power in a damp environment.

If, due to limited space, the maximum insulation thickness is low, PIR and PUR foam boards constitute an attractive option. With excellent thermal conductivity coefficient, they make an unrivalled solution allowing you to reduce the insulation thickness by half. It is best to use thermal insulation materials in the form of boards with profiled edges which allow joining boards with overlap.

Spray polyurethane foam has created an alternative for thermal insulation boards. Spray system allows you to eliminate faults and gaps between boards and to make a smooth transition of the insulation into the attic style and ensure even thickness of insulation of very high quality. This insulation is tight, light, and perfectly adheres to the surface.

Polyurethane foam has the same insulating parameters as the above-mentioned PIR and PUR boards, but it eliminates such disadvantages as the necessity to cut the boards or the gaps between the boards. Furthermore, depending on the position of waterproofing, polyurethane foam provides an even base for it or additionally seals it from the outside. If you decide to use polyurethane foam on your roof, be sure to provide appropriate protection against UV radiation.

Thermal insulation of a ventilated roof — how to design it?

We deal with a ventilated roof if there is a ventilated air gap between the ceiling structure and the roof. It has a positive impact on thermal conditions of a building, although with today's knowledge and requirements, it is not necessary to achieve satisfying results.

In the case of a ventilated roof, thermal insulation is laid directly on the ceiling structure. Because this solution does not require high compression strength and there is no impact of external factors, the basic parameters taken into account is thermal conductivity coefficient.

In such circumstances you can use the previously referred to Styrofoam boards and mineral/wood wool boards. Spray foam insulation would also prove particularly useful, because it perfectly fills every cavity. Remember that it provides better insulating parameters compared to the above-mentioned materials.

If the ventilating gap is small, you can use the method of blowing thermal insulation material into that space — cellulose, mineral-wool-based granulate, or Styrofoam. Blowing thermal insulation allows reaching every little recess, where it is impossible to lay insulation in a conventional way. Alternatively, you can lay insulation before mounting the roofing.

In the case of a ventilated roof, the thermal insulation surface is separated from the roofing surface. The role of the air circulating between these surfaces is balancing the pressure, free water vapour transmission, and reducing the extent to which the layers over the ceiling structure heat. This solution is beneficial from the point of view of thermal properties and dampness.

At the lowest point, the ventilated gap should be at least 5 cm high; optimally, it should be 10–15 cm high or higher. It is important to create vents (be sure to protect them against birds and rodents with mesh) which will allow free air flow and prevent the accumulation of moisture.

Insulating a flat roof with polyurethane foam — definite advantage

Closed-cell polyurethane spray foam will prove ideal for thermal insulation of a flat roof. Such an insulating solution involves applying several layers of PUR foam, with each layer around 1–2 cm thick. The effective roof insulation layer may range in thickness from 3 to 12 cm, as needed.

Closed-cell polyurethane spray foam will prove ideal for thermal insulation of a flat roof. Such an insulating solution involves applying several layers of PUR foam, with each layer around 1–2 cm thick. The effective roof insulation layer may range in thickness from 3 to 12 cm, as needed.

An advantage of using this material is that it provides light, durable, and jointless coating with perfect thermal insulation properties. It ideally adheres to the surface and makes an excellent base for applying the outermost layer. Along with the layer protecting against UV radiation and stagnant water, PUR foam perfectly protects the roof against unfavourable weather conditions, such as rain and wind.

For spray foam, spray or painted coating systems are recommended, but there is nothing wrong with using PVC membrane or heat-welded bitumen membrane glued to the surface. It would be a shame to pierce such an excellent insulation with metal fasteners.

This website uses cookies. By using this website, you consent to the use of cookies in accordance with your browser settings.

This website uses cookies. By using this website, you consent to the use of cookies in accordance with your browser settings.